3D Printing is an additive manufacturing process. The main objective of the 3D printer is to convert the CAD design saved as a digital file from the computer into 3D dimensional objects. These printers are not your ordinary run-of-the-mill commercial printers. It is called 3D printing because it is based on the idea that if you print the same design using ink or similar material, it repeatedly which forms a layer of the 2D design into a 3D model. But before we proceed further, let us discuss what exactly is rapid prototyping and additive manufacturing?

What is Additive Manufacturing?

In the additive type of manufacturing, the desired form of the design is achieved by adding layer by layer of successive layers of material. This is in stark contrast to subtractive methods where the desired design is achieved by the elimination of the material of the workpiece.

What is Rapid Prototyping?

It is a manufacturing methodology of creating prototypes at rapid cycle time, hence the word rapid prototyping. 3D printing is suited for rapid prototyping because it is fast and relatively cheap to most methods available. It does not involve any expensive tooling or equipment.

However, 3D printing is slowly gaining prominence in usage for rapid manufacturing which is a new method of using 3D printers for small batch custom manufacturing.

But the process is not so simple, so how does it actually work?

Process of 3D Printing

There are three crucial steps in the process of 3D Printing. They are mainly:

1. Sketching.

2. Slicing.

3. Printing.

1. 3D Printer – Sketching

Let’s start with the first process, sketching is the process of designing a product to actualize the design in the 3D format on the computer. The design of a product is dependent on the specifications or requirements of the customers. The 3D format is basically a model based on the design sheet. The model can be created yourself or downloaded from a 3D repository if you decide to do it yourself, you can use a 3D scanner, an app, haptic device, code, or simply use a 3D modeling software.

The model is sketched using various CAD software such as Tinkercad, SketchUp, PTC Creo, SolidWorks, and much other such software available in the market. Tinkercad is open-source offers beginner lessons as well as built-in features. The CAD drawing is then converted to the standard tessellation language (STL) format. Most 3D printers use STL files in addition to other file types such as ZPR, ZPR, VRML, ObjDF, AMF, Code, and other formats. This file extension format is for stereolithography CAD software which was created by 3D Systems, one of the early adopters of 3D printing technologies. It is extensively used for 3D printing and related activities.

2. 3D Printer – Slicing

The next process is slicing. Slicing is dividing a 3D model into multiple horizontal layers and is done with the help of slicing software.

Slicing in simple terms is slicing the CAD model vertically into thin slices of layers. These layers are useful for the printer to understand the model. The slicing concept brings about easier incorporation of converting the model from the computer to the printer head. Some of the most popular software used for slicing the CAD model are CURA, CraftWare, and Astroprint.

This software also handles the fill of the model by creating a lattice structure around or inside the model for stability of the printing process, fill rate, thickness, and width of the fill. These parameters can gauge the time period of the printing process. So, special care should be taken care of to alter these parameters to find the minimum time period to print it. The software also takes care of the addition of support columns which aid in the support of the melted material from falling off.

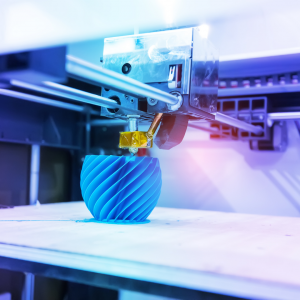

3. 3D Printer – Printing

Next, the computer is connected via USB, or SD, or internet, and slicing CAD file is sent to the printer.

The last process is printing, there are many techniques and mechanisms involved in the printing process. So the printer differs from model to model based on these techniques and mechanisms. One of these methods will be discussed in detail, that is, FDM which stands for fused depositional modeling, in this method, the plastic or any other suitable material is used, is extruded through the nozzle fixed at the printer head, which is control by two axles attached to a rack and pinion arrangement.

These arrangements are moved by actuators controlled by the computer. This automated mechanism where, the printer creates a model over a period of time depending on the model and the filling specifications by turning a 3D CAD drawing into lots of two-dimensional, cross-sectional layers made of 2D prints that sit one on top of another This process involves the melting of the printing material and placed on the printing bed, layer by layer, while the printing head moves about the 2-D shape configuration of the model, from the outermost point to innermost point of the design, which then moves to the next layer and further repeat the process until the desired thickness as per the model is achieved.

There are several other techniques such as binder 3D printing, photopolymerization, and sintering. These methods variate in the process of printing but printing is done layer by layer. The process of printing may take an hour or even days, depending on the design complexity, feed specifications, and the model of the printer.

Overall, the process of 3D printing has been covered. This process can be applied to various other materials like metals and hot chocolate!

The last step is post-processing. Many 3D printers require some type of post-processing, such as brushing off any remaining powder or washing the printed object to remove water-soluble supports which may also need curing.

3D printing is still beyond widespread customer adoption and the technology is still hype beyond market acceptance. This is normal for any cutting-edge technology. The technology is still in its infancy and is quite expensive, but it holds promise. In the not-so-far future, it will be used everywhere from making metal sheets to cakes, and will be used by everyone from designers to entrepreneurs.

How to Learn 3D Printing Design?

Labdox is a platform to help learners acquire core engineering and entrepreneurial skills in emerging technologies. Labdox provides a one-stop place for validated and Industry mapped courses from around the globe.

Labdox provides the wonderfully designed online 3d printing Course, Register yourself and starts learning!