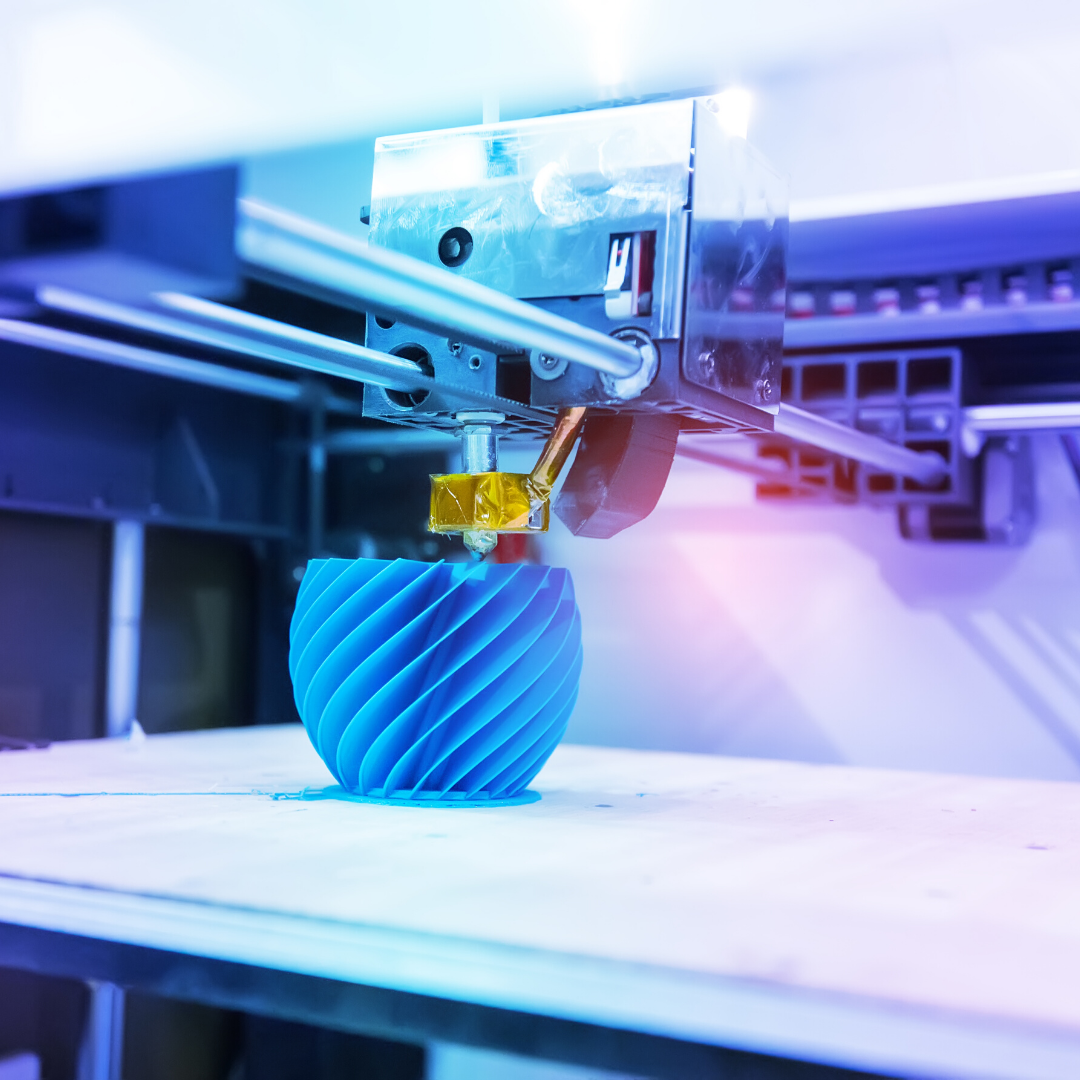

Cars. SUV, convertible, off-road, vans, sports car. These vehicles have helped transport us anywhere we want to go. They are also pretty costly. Apparently, some of their parts can be created by 3D printing. This could prove useful for the automotive industry as they are customizable, cheaper, and much faster to manufacture. Here are some examples of the application of 3D printing technology in the mechanical and automotive industry.

Printing and Prototyping

Prototypes always come before production starts. Engineers can now create fully functional miniatures to full-scale models with 3D printers. More than that, the machine can also print out rapid prototypes of tools and replacement parts on-demand. This will save time & money, and reduce the impact of product recalls that will tarnish the companies reputation.

Replacing Rare Spare Parts

Some car parts are rare and hard to come by. It could be because the car is antique or only present on limited-run vehicles. 3D printing the parts could be the solution. This process could be more cost-effective. It also requires less amount of warehouse space because they can be made within hours or days. 3D printing has been used to build prototypes, jigs, and fixtures, tooling, low-volume end-user products, concept models, and reproducing parts.

Bespoke Car Designs

Conventionally, car designs are not something you can customize. Specifically their models and the look of the vehicles. Customizing how your car looks can be done with 3D printing. Though most of them are done on expensive cars. Though they usually use a premade stock models from the dealership floor.

Lighter Cars and Higher Fuel Efficiencies

Companies have been developing lightweight vehicles for decades. 3D printing can achieve that by creating latticed parts made of aluminum. They are strong, safe, and able to reduce weight by up to 80%. Also, the lighter they are, the less fuel they will consume. Thus the amount of carbon dioxide and monoxide released may be reduced. 3D printing also allows the reduction of waste and the overall production cost of the vehicle. Therefore, purchasing them might be more accessible.

Fully 3D Printed Vehicles

The technology of 3D printing needs to be developed more. Because printing out vehicles are not yet possible. One of the main problems here is the assembly time. A conventional modern assembly line can build an entire car in under 90 minutes. To do something similar, a 3D printer needs days, weeks, even months. Therefore, more research is needed to shorten its time.

Conclusion

Various industries are already aware of the benefits of 3D printing. More and more are implementing them in their manufacturing processes. These are good and all, but the industry still faces many challenges. Low production speed, the machine’s limitation in producing larger parts, and a shortage of skilled technicians are a few things that hinder the usage of 3D printing in the automotive industry. Also, 3D printing fully functional vehicles might need some more time. You might not see fully printed vehicles anytime soon. But it is not an impossibility. We just have to wait a little longer.

To gain more in-depth insights into 3D Printing Technology In Mechanical And Automotive Industry. Register for the 3D Printing course brought to you by Labdox.